PRODUCT FINDER

Which products are best for you?

Core Cutter Upgrades

Auto Indexing Knife

Hands Off Blade Adjustment

Simple Operation

The operator sets the cycle counter based on your experience with the cores you regularly cut. The indexer will advance the knife 3/16" on its circumference each time the count is reached. Should a knife be prematurely damaged, the operator can signal an advance to the new edge. The only time the operator handles the knife is when it has indexed a full revolution and needs replacement. This counter can be panel installed in new cutters, or provided as an "add-a-panel" kit for core cutters already in service.

Easy Installation

We provide retro-fit kits for all models of Appleton Core Cutters. A control panel is mounted to the cutter frame, the knife holder is swapped out and air and electrical connections made per the included instructions. All parts and fittings are included. PLC controlled units may require a program upgrade. The conversion takes between one and four hours dependent on core cutter model.

Instant Diameter Change System

Quickly Change Diameters Without Changing Mandrels

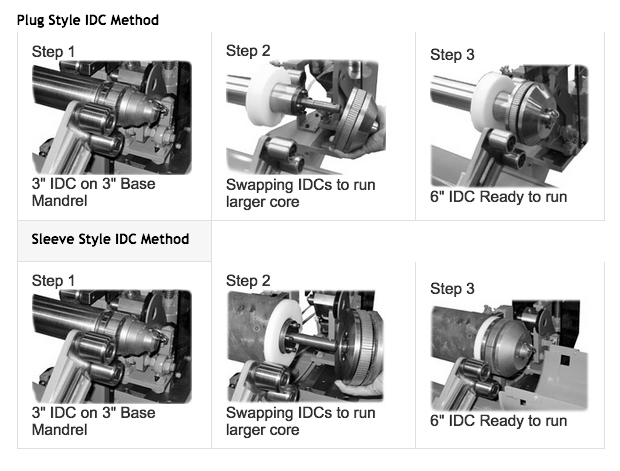

Appleton's patented Instant Diameter Change (IDC) Mandrel System provides a multiple core diameter capability with a single mandrel and interchangeable cartridges.

IDC Overview

The IDC system features a mandrel with a heavy duty drive to handle a specific range of diameters. The IDC base mandrel is built to the smallest diameter of each range. Lightweight Sleeves or End Plugs provide support for larger core diameters. The patented IDC cartridge is a pre-assembled unit that includes the head jaws, cone, springs and pad mounting cup. The components are optimally adjusted, requiring only that the operator slide the assembly onto the pull rod and secure it with the quick release pin.

Fits all Universal Models

This system will fit existing S200 and S210 Semi-Automatics,

A300 and A301 Automatic Core Cutters, A350, A360, A400 Hydraulic Core

Cutters, P500 and P510 Programmable Core Cutters (programmable cutters may require program changes). Note that an IDC base mandrel is required for the IDC cartridges.

* With modifications the Instant Diameter Change System(IDC) can be

added to most Pre-Universal Appleton Core Cutters such as Model(s) BI,

D, S or others. Contact Appleton Mfg. Division to verify availability.

Base Mandrel Diameter Range

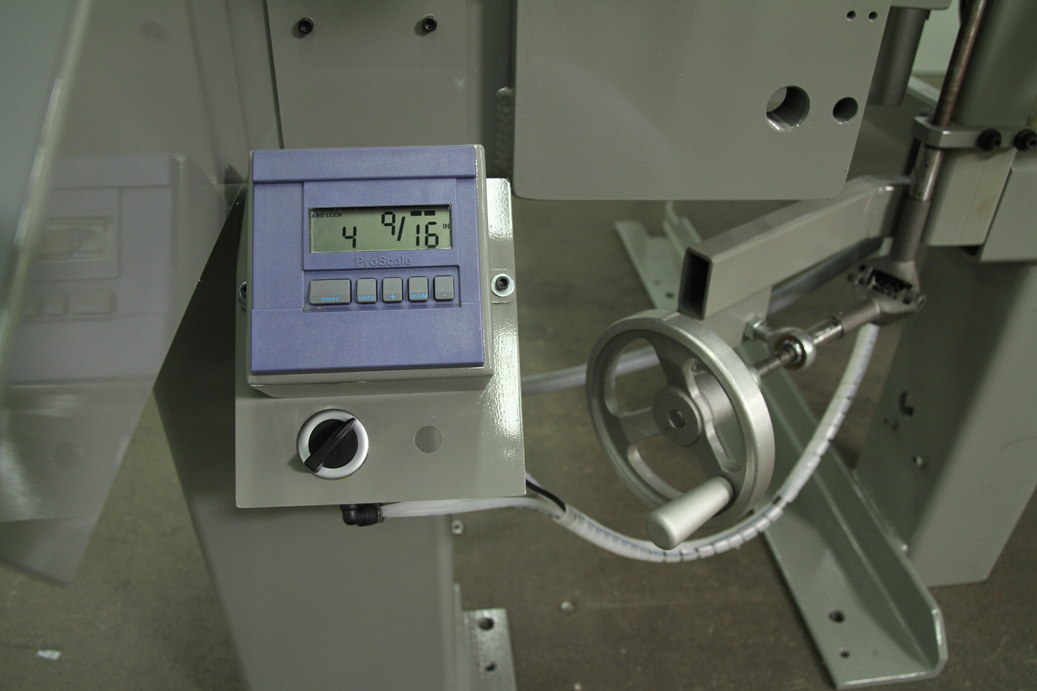

Digital Readout

Digital Readout

Eliminate a Source of Cut Length Error

This high-precision electronic device has a digital display unit and linear scale which eliminate visual measurement guesswork, and reduce machine setup time. The display can be easily switched to provide output in decimal inch, millimeters or fractions (1/16, 1/32, 1/64).

Digital Readout for New or Existing Core Cutters

Available on:

Installation

This 4 hour procedure requires that the target tube be removed, holes drilled, and the scale mounted. Tube supports in the cutter frame are also removed, holes drilled for brackets and the digital display mounted. The wiring is straight-forward as the Digital Readout is battery powered.

ABS Hoods

Replacement Hoods

Replacement for Sheet Steel Hoods

Approximately a 40lb difference in weight between the sheet steel hoods and the ABS Plastic Hoods.

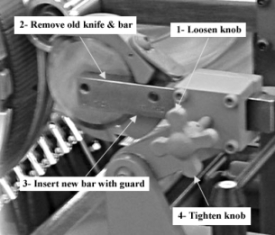

Model D, BI & S Knife Guards

Enhanced Knife Guarding

For Appleton Model D, BI and S Core Cutters

This retro fit improves the knife guarding mechanism on pre-universal series Appleton Mfg. Division core cutters. The newer Universal series core cutters were designed to provide an area guard to protect the operator during cutting operations and a fixed guard for additional protection during mandrel changes.

The New Guard Provides

Enhanced Knife Guard Kit Includes

Previous Knife Configurations that Enhanced Knife Guarding Replaces

Enanced Knife Guarding Installs Easily

The guard covers the entire knife. Only the portion actually engaged in the core wall is unsheathed as needed. The maintenance lock is easily engaged, ensuring operator protection during mandrel or cutting pad changes.

Model S Knife Retro Fit

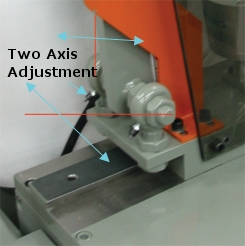

Knife Air Assisted Conversion

Retro Fit for Model S Core Cutter from Appleton Mfg. Division

This retro fit option adds the functionality of a powered knife, full range knife adjustment and operator foot pedal to Model S Appleton core cutters.

Benefits of Installing the Model S Retro Fit

Easy to Install - The assembly comes with complete mounting instructions, making installation a snap.

Which products are best for you?

Back to Top