PRODUCT FINDER

Which products are best for you?

Multi Diameter High Speed Core Cutter

Appleton Multi-Diameter High Speed (MDHS) Core Cutter – The Perfect Solution to the challenge of profitable short run orders

The MDHS features chucked core positioning for cut length accuracy and two opposed knives – providing rapid cutting. Of course, the “classic” Appleton fixed blade cut provides a clean burnished cut. The MDHS core cutter provides quick internal diameter changeover utilizing low cost tooling.

Specs

MDHS.S

MDHS.M

Both Models

Utilities

Connectivity

Production Range

Upgrades

Automated Core Handling

Systems to load and unload your parent and cut cores. See our Appleton Automation™ web page for more details.

Printing System

Prints cut core length along core circumference.

Articulating Cut Core Accumulator Table

Trim and butt waste can be automatically separated from the cut cores. Cut cores can be discharged as they are cut, or accumulated for a single transfer to an accumulator table or conveyer. We can provide cut core handling systems with both side and end discharge to load bins and shafts.

Knife Lubrication System

Knife lubrication is available via a dual drip feed lubricator. The drip feed rate is individually adjustable for each knife.

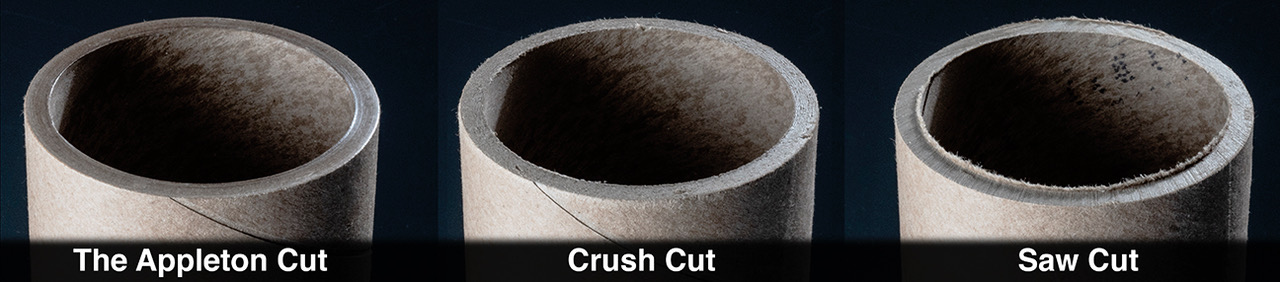

The Appleton Cut

Appleton Manufacturing is the only core cutter manufacturer utilizing the specific combination of a fixed knife to slit the core and internally-driven core rotation while supporting the inner ply with a carbide pad, which is used to pinch the inner ply of the core between the cutting edge of the knife, allowing for a consistently accurate and clean cut all the way through the core. This technology allows for every core cut on an Appleton to have a crisp, clean and virtually dust-free polished cut. It’s what we at Appleton call “The Magic of the Appleton Cut”.

Appleton Manufacturing’s Core Cutters offer several benefits to slitting a core as opposed to saw or crush cutting them:

Appleton’s cutting technology is available on all Appleton Core Cutters from our basic Semi-Automatic S210, through our Automatic A301 and A400s, as well as the Programmable P510 and P520 and up to our fully automated P610 and Multiple Diameter High Speed (MDHS) cutters.

Lower Quality Core Cutting Types

Which products are best for you?

Back to Top